TI Supports Learning Innovation With Embedded Systems

The original laboratory equipment designed for the required class could not be easily used when students began remote instruction.

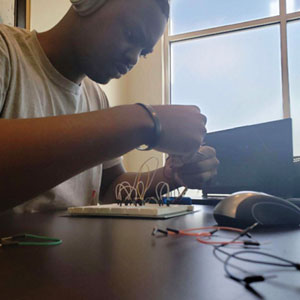

Students are now able to practice hands-on skills at home because of the kits, originally provided by Texas Instruments Inc. (TI) because of the COVID-19 pandemic. Nikoubin and others in the Department of Electrical and Computer Engineering (ECE) in the Erik Jonsson School of Engineering and Computer Science are continuing to teach several courses using the kits. Compared to the traditional laboratory settings, learning at home allowed the experience to better fit a student’s needs. For example, when students no longer needed to reserve laboratory time, those who needed to take more time to master skills and content were able to do so. Self-motivated students who practiced homework problems multiple times also performed better on exams.

Additionally, the smaller scale technology is more comparable to what they will encounter in their careers.

“I am trying to make connections between work and their skills for the jobs,” Nikoubin said. “Once they uncover their interests, they will also have the skills they need to move forward.”

Dr. Tooraj Nikoubin, professor of instruction, holds the technical equipment kits that allow students to complete lab work at home. Texas Instruments Inc. provided the pared-down technology.

“The TI equipment really helped us get hands-on experience with devices and circuits.”

– Sangeetha Tatineni BS’21

“I had the components needed to practice and hone my skills as an engineer. I expect to run into issues and sometimes fail, but I take those as a learning experience to grow.”

– Sean Njenga BS’22

“The kits provided the equipment necessary for me to learn about some of the fundamental electrical components used in the industry.”

– Abdullah Abdulhameed BS’22

“Students like me were able to continue learning despite the circumstances due to the pandemic. Without access to these materials, we would have missed out on learning opportunities that are extremely important in our development as competent engineers.”

– Sehar Malik BS’22

“Not only have our labs been challenging, but fun as well. We couldn’t have done this without this kind donation.”

– Nicholas Wagner BS’22

When classes at UT Dallas and most other universities throughout the country were moved online because of the new coronavirus, Nikoubin and his teaching assistants initially recorded lab experiments using practical lab equipment with as many details as possible. At the same time, the simulation portion of all lab experiments was redesigned to become an online meeting platform.

“I used prerecorded lectures along with live lectures,” Nikoubin said. “We modified lab reports to questions and answers on eLearning instead of regular procedures to help students understand when they should use the online platform which has limitations.”

Though recordings provided content for the initial semesters of remote education, Nikoubin knew the hands-on experience was the most critical. He was unsatisfied with providing simulations for hundreds of students until the campus could safely reopen.

“For some courses, providing recordings was sufficient,” Nikoubin said. “We knew we needed to push for something else.”

In addition to the standard electronic equipment, the lab course requires the use of several tools and programs including Excel, C programming, LabVIEW, OrCAD for PCB Design, Pspice® and MATLAB.

Students previously worked together in groups of two to share the electronics equipment in a laboratory setting. For months after the pandemic’s onset, students could not access the space. While many students packed up computers and other devices, the bulky lab equipment, which costs between $10,000 and $20,000, could not be transported to students’ homes, and leaders did not want to ask students to purchase costly equipment kits.

Ultimately, TI came to the rescue and provided kits using the most current technology that would teach and reinforce the same skills as an onsite laboratory experience. Each kit eventually included an integrated circuit and testing and measurement tools packed into a container small enough to fit inside a shoebox as a new and advanced embedded system.

“We looked at courses where students would require laboratory instruction,” said Ayesha Mayhugh, a former TI representative. “Hands-on training at this stage is vital to them. They would not have the same marketable skills with only a lecture as they received from practical implementation through the lab component.”

Overall, TI contributed more than $102,000 in equipment for more than 300 students each semester of remote instruction.

The kits are now used in as many as six courses.

“With the consideration of available advanced embedded devices, Lab at Home is more than a solution,” Nikoubin said. “It is a new culture.”

Dr. Lawrence Overzet