IDEAS TAKING FLIGHT

The laboratory acts as a home — a nest — for these ideas to incubate and hatch.

The journey from nest to flight is never perfect. Ideas grow with iteration. Just as young birds make several attempts to leave the nest, research can face false starts. However, through trial and error, University of Texas at Dallas engineers and computer scientists have watched their work propelled far beyond campus.

Recently, discoveries and devices born out of Jonsson School labs have successfully soared into new worlds of industry and landed in new branches of exploration.

SOARING AT THE QUANTUM SCALE

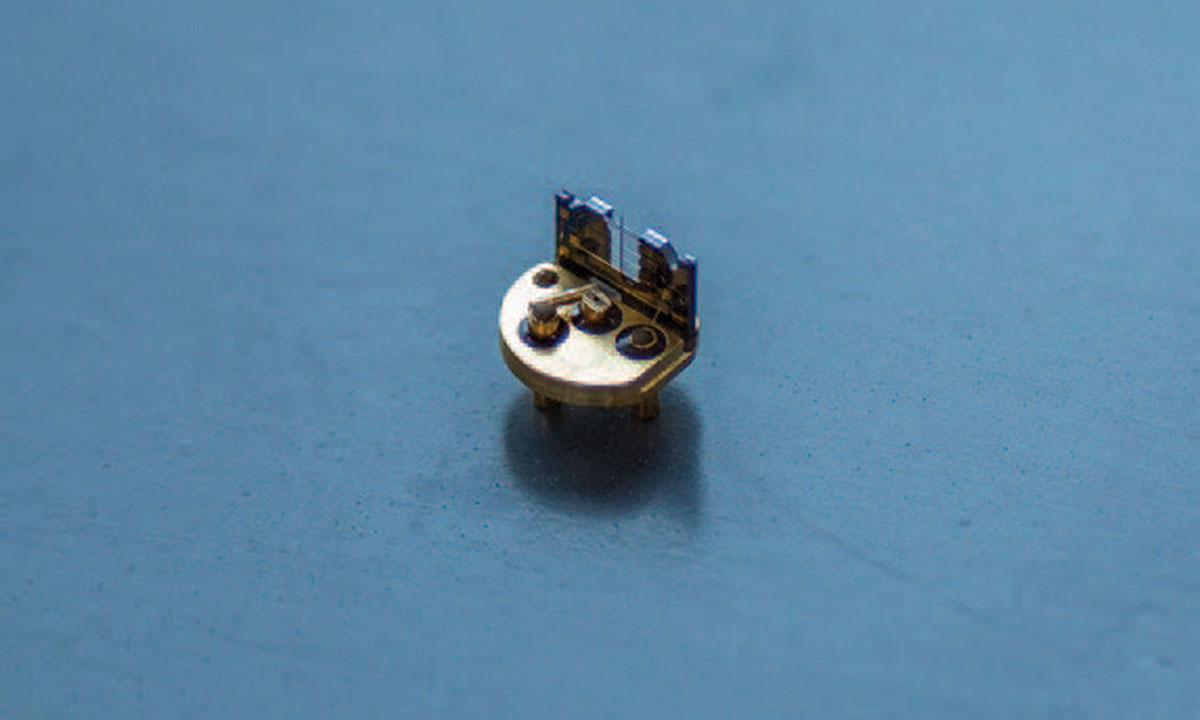

High-precision equipment is key to the fabrication of nanoscale quantum devices. Above, a scanning tunneling microscope (STM) is used to construct a device atom-by-atom. Below left and right, STM images show atomically precise patterns produced by this high-resolution lithography method. This technology can be used for the fabrication of quantum computer bits (qubits) and other solid-state quantum devices.

A UT Dallas researcher has partnered with a North Texas company to commercialize technology developed in the lab. The new tech makes it possible — for the first time — to manufacture tiny quantum devices on a large scale.

Dr. Reza Moheimani, the James Von Ehr Distinguished Chair in Science and Technology, and Zyvex Labs received funding from the United States Department of Energy (DOE) for their work. A Small Business Technology Transfer award worth $1.1 million went to Moheimani to support his research over the next two years. Zyvex Labs, which specializes in developing atomically precise manufacturing devices, also received $1.1 million.

“Quantum computing has the ability to transform fields, but the technology to manufacture these devices on a large scale is still emerging,” said Moheimani, also a professor of systems engineering in the Jonsson School, who detailed how his research team discovered greater control and precision of the fabrication process in the Journal of Vacuum Science & Technology B.

Moheimani received a $2.4 million grant from the DOE in 2019 to help catalyze his work examining the manufacturing of quantum devices.

“What we are doing is what universities are meant to be doing,” Moheimani said. “You’re not supposed to be working in a vacuum — you’re meant to be interacting with industry, and what we’re doing complements each other’s abilities and skills.”

Dr. Reza Moheimani introduces a nanoscale quantum device. This tiny innovation packs grand implications.

HOMEGROWN COMPANY: FLOCKS TO SUCCESS

Dr. Walter Voit is pushing the limits of 3D printing through flexible polymers and mass production of nasal swabs during pandemic shortages.

The company, which was founded by Dr. Walter Voit BS’05, MS’06, was acquired by Desktop Metal Inc., an industry leader in additive manufacturing based in Burlington, Massachusetts. Voit, associate professor of materials science and engineering and mechanical engineering in the Jonsson School, will continue to serve as CEO.

Through his research, Voit has developed specialized plastic and rubber materials using 3D printing. The acquisition makes way for large-scale manufacturing of these materials, which can be used for products ranging from shoes to parts for airplanes.

The Venture Development Center provided space to Adaptive3D for years, while the Office of Research and Innovation and the Office of Technology Commercialization helped with intellectual property and licensing.

Making space for growth, the company is naming Richardson’s Innovation Quarter as their new home, a move that will quadruple the company’s footprint.

With Adaptive 3D’s mission for broad impact, students in UTDesign®, a senior capstone program, recently researched COVID-19 pandemic-related problems under Voit’s direction.

“We will pick up from where the student teams left off with their designs to find a development pathway to scaling their systems to handle high-volume manufacturing of millions of swabs per month,” Voit said.

In the News

Dallas Innovates

Community Impact

UT Dallas Primes Tech Talent Pool Amid Surge in Demand in Richardson and Beyond

Dallas Innovates

UTD 3D Printing Spinoff Acquired by Desktop Metal

A BIRDS EYE VIEW OF THE PANDEMIC

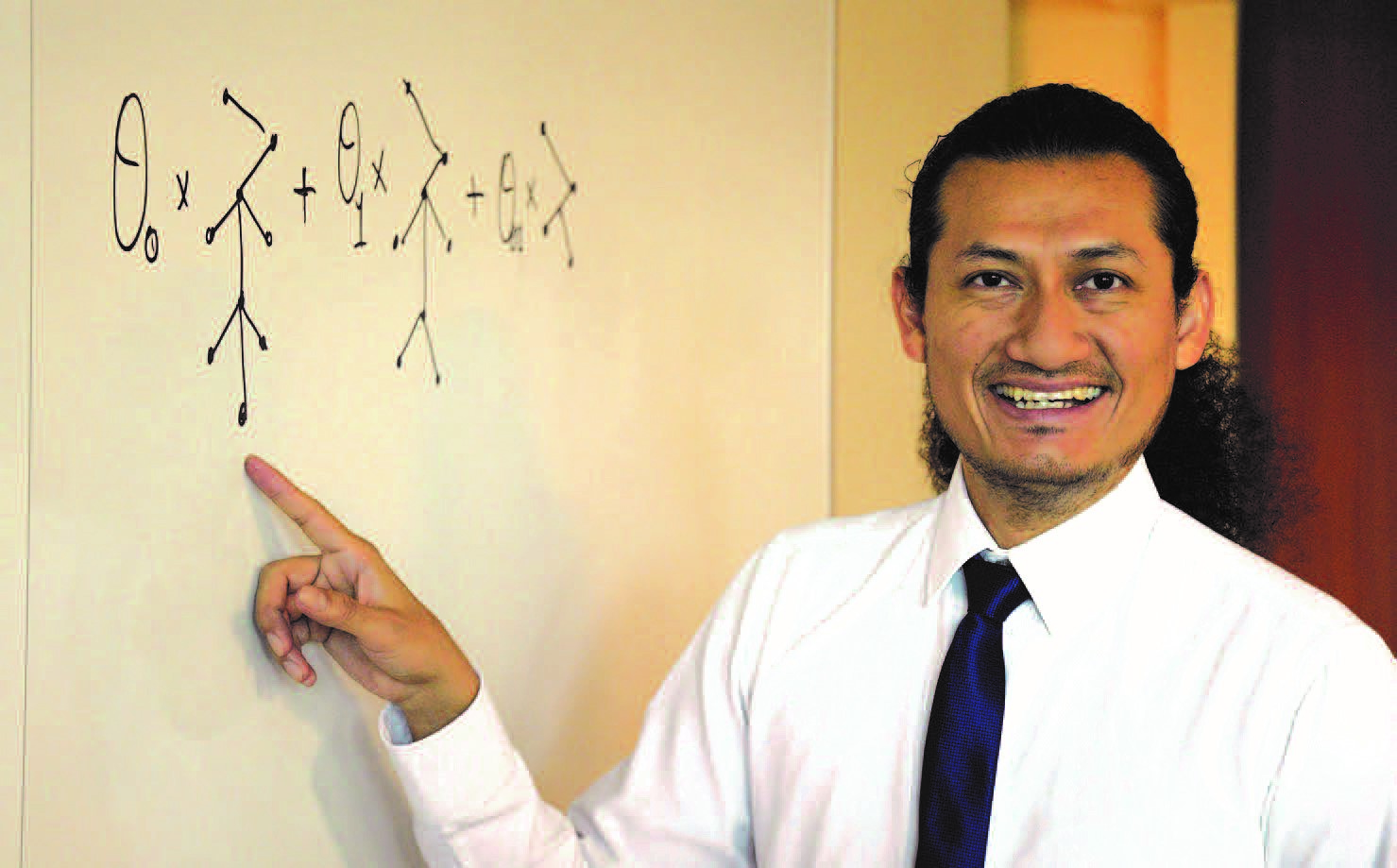

Dr. Ignacio Segovia-Dominguez, a postdoctoral research associate in the Department of Computer Science in the Jonsson School and the Department of Mathematical Sciences in the UT Dallas School of Natural Sciences and Mathematics, teamed up with the NASA Jet Propulsion Laboratory to show that air quality and COVID-19 hospitalization rates were uniquely tied together.

By pulling data from several government agency satellites and plugging complex spatiotemporal information into a geometric deep learning computer model, Segovia-Dominguez determined that three factors — temperature, relative humidity and the number of aerosol pollutants in the air — could help predict the severity of COVID-19 outbreaks.

“The seasonal flu is tied to temperature, but COVID-19 did not seem to be heavily related,” he said. “We weren’t expecting the two — the flu and the coronavirus — to behave differently in that regard.”

Dr. Ignacio Segovia-Dominguez uses a geometric deep learning computer model to solve another pandemic problem — predicting where the next severe outbreak will occur.

In the News

NBCDFW

UTD Researchers Show Connection Between Air Quality and COVID-19 Severity

The Dallas Morning News

UT Dallas Researchers Connect Texas Air Quality With COVID-19 Severity

ConTexere

Using Geometric Deep Learning to Predict COVID-19 Outbreaks

As the lead author on the study, Segovia-Dominguez noted that relative humidity is likely the biggest factor in determining whether the coronavirus will survive in certain environments. While the flu virus thrives in less-humid areas, COVID-19 may be more tolerant.

This study highlights the intrinsic relationship between air quality and COVID-19 clinical severity, with insights on new ways to predict geographical areas at higher risk of having higher concentrations of coronavirus. As demonstrated by the new findings, NASA’s satellite data will play a more prominent role as researchers develop reliable predictive platforms for future epidemiological monitoring.

The Jonsson School researcher added that these findings encourage new branches of inquiry.

“It makes you think; it motivates you.” Segovia-Dominguez said. “I want to continue to explore and push forward to make a difference.”

PERCHED TO PROVIDE RAPID DETECTION

A team of bioengineers in collaboration with the company EnLiSense have designed a wearable sensor that can detect markers of viral infection in sweat. This jump in early detection measures passive sweat, so users don’t have to actively engage in physical activity to yield results. And, monitoring happens in real-time.

“We have built a technology to unlock and explore the latest frontier in sweat diagnostics,” said Dr. Shalini Prasad, head of the Department of Bioengineering in the Jonsson School and the Cecil H. and Ida Green Professor in Systems Biology Science at UT Dallas. “This wearable technology is truly transformational in that it can measure and report human host response messenger molecules associated with inflammation and infection in a continuous manner.”

The first author of the study was Badrinath Jagannath PhD’21, who received a first-tier Baxter Young Investigator Award and David Daniel Thesis Award from the UT Dallas Office of Graduate Education for his research on the sensor technology. He recently became a postdoctoral research fellow at the Wyss Institute at Harvard University.

Badrinath Jagannath PhD’21 (left) earned several awards for his PhD work with Dr. Shalini Prasad (right) on sensor technology.

Prasad leads by example as she encourages others to pursue tech-commercialization opportunities.

Easily used at home, the portable, reusable breath test device was designed by Dallas biotech company SOTECH Health, which licensed the platform technology that Prasad developed and further optimized through the University’s Intellectual Property Assignment/Sponsored Research Agreement (IPA/SRA). The company has submitted the device to the U.S. Food and Drug Administration for emergency use authorization.

“The pandemic presented a myriad of research questions, and we worked to find some answers quickly,” Prasad said. “The idea is to screen people rapidly to help prevent any further transmission.”

The device works by identifying molecules that show an infection in breath. If the patient presents positive, then a COVID-19 polymerase chain reaction (PCR) test would be administered.

“This way of screening patients helps to sort out who needs

further testing or care immediately,” Prasad added.

In the News

Dallas Innovates

UTD Team’s Wearable Sweat Sensor Can Detect Key Biomarkers of Infection

Dallas Morning News

UT Dallas Scientists Develop Early-Stage Sweat Sensor to Monitor COVID Immune Response