Collaboration Leads to New Center, University’s Largest Grant

As electric vehicles and renewable energy sources including solar and wind are scaling production, researchers across the globe are racing to develop a critical system component — grid‐scale battery storage. Faculty from the Erik Jonsson School of Engineering and Computer Science at the University of Texas at Dallas discovered that they did not need to travel far to supercharge their research efforts.

Dr. Kyeongjae (KJ) Cho, professor of materials science and engineering, along with postdoctoral researcher Dr. Taesoon Hwang, joined Dr. Guoping Xiong, assistant professor of mechanical engineering and Siyu Tian, a doctoral candidate in Xiong’s lab, to test if a commonly available clay additive could help extend the stability of aqueous zinc‐ion batteries (AZIBs).

After the experimental and theoretical researchers began working together in December 2022, they secured an almost $600,000 National Science Foundation award in June 2023. By September 2023, the Batteries and Energy to Advance Commercialization and National Security (BEACONS) center was announced at UT Dallas to implement a $30 million grant from the U.S. Department of Defense toward battery research including AZIB systems.

“The innovations from KJ and Guoping are primed to make maximum impact, and their commendable success shows why we have a strategic focus on research collaboration,” said Dr. Stephanie G. Adams, dean of the Jonsson School, holder of the Lars Magnus Ericsson Chair and professor of systems engineering.

“At the Jonsson School, we have recently identified five primary research thrusts with six cross-cutting technologies. Energy science and technology is one key research thrust where we have a competitive advantage in Texas and where we may see exponential growth in the coming years.”

GRID-SCALE BATTERY DEVELOPMENT

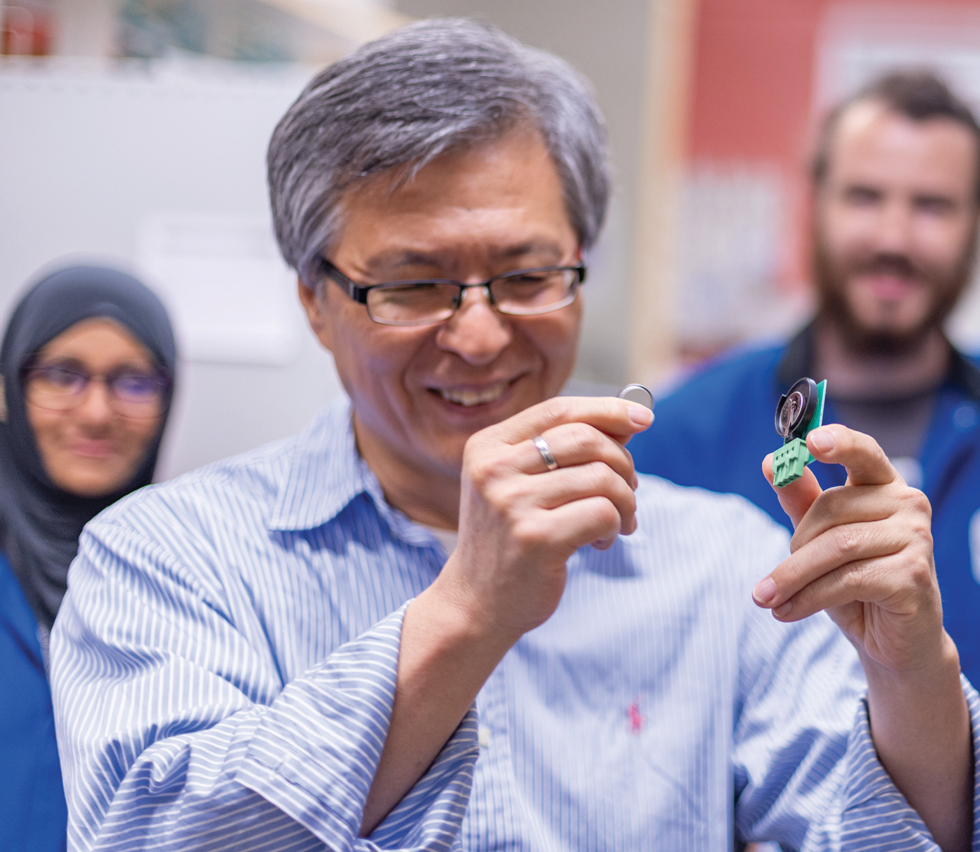

Most materials used for battery fabrication need to be handled with utmost care, but the two swelling clay additives used for aqueous zinc ion batteries (AZIBs) are an exception. Tian shows how laponite and bentonite can be shaped like putty.

“Grid-scale battery storage is needed, especially for wind and solar energy,” Cho said. “AZIBs are extremely stable and suitable for large-scale stationary applications. They can take up space — as much as an entire city street corner underground — without safety concerns, but they need to have better energy density and cycle life.”

Lithium-ion batteries are ubiquitous in smaller devices, such as computers and cell phones. The batteries are now also used for electric vehicles and to provide backup power storage to individual homes with solar panels. However, they have several drawbacks, particularly for large-scale implementation.

Lithium-ion batteries also require several rare metals to produce, including cobalt, nickel and lithium.

“We have begun mining for cobalt again recently in the United States,” Cho said. “However, if we want to use renewable energy as a more environmentally friendly choice, then we’re probably defeating the purpose by focusing on rare metals for large batteries.”

AZIBs function in a similar way to lithium-ion batteries, but they are ultrastable and are not prone to catching fire when they are damaged since water electrolytes are intrinsically safe compared to combustible organic liquid electrolytes in lithium-ion batteries. However, when the zinc metal is submerged in a water-based electrolyte solution for an extended time, unpredictable side reactions can occur.

There are ways to separate the zinc from the contacting water in such batteries, Xiong said, but adding a coating on the zinc surface typically adds time and more costly materials to the process. So, Xiong’s lab used a unique additive — swelling clay — to improve the batteries’ performance by reducing the water activity.

“With AZIBs, the thermal runaway is not a concern,” Xiong said. “We’re looking more at extending the batteries’ performance and cycle life.”

A Powerful Combination

While Cho is well-known in his field, he previously focused on collaboration with experimental researchers in Korea where he has connections with industry and research institutes, in addition to the United States.

“I have been working on batteries for more than 10 years since I joined the University in 2006,” Cho said. “I did not know anyone locally who was focusing on my particular area of battery research. The partnership has been really productive, really fast since Guoping reached out.” Cho was immediately interested when Xiong described a creative approach to stabilizing the AZIBs.

“When I heard that he was using the swelling clays, I thought ‘That’s just perfect,’” Cho said. “I knew that the battery would be extremely stable because of the water solution, but these clays can reduce water activity to improve the cycle life as an affordable, commonly available additive. The clays would meet all the requirements and provide an innovative solution.”

This collaboration is mutually beneficial. Cho’s group provides theoretical analysis and recommendations based upon the atomic fundamental properties of the battery components and their interactions, and Xiong’s group provides experimental results and validates predictions made by Cho’s group.

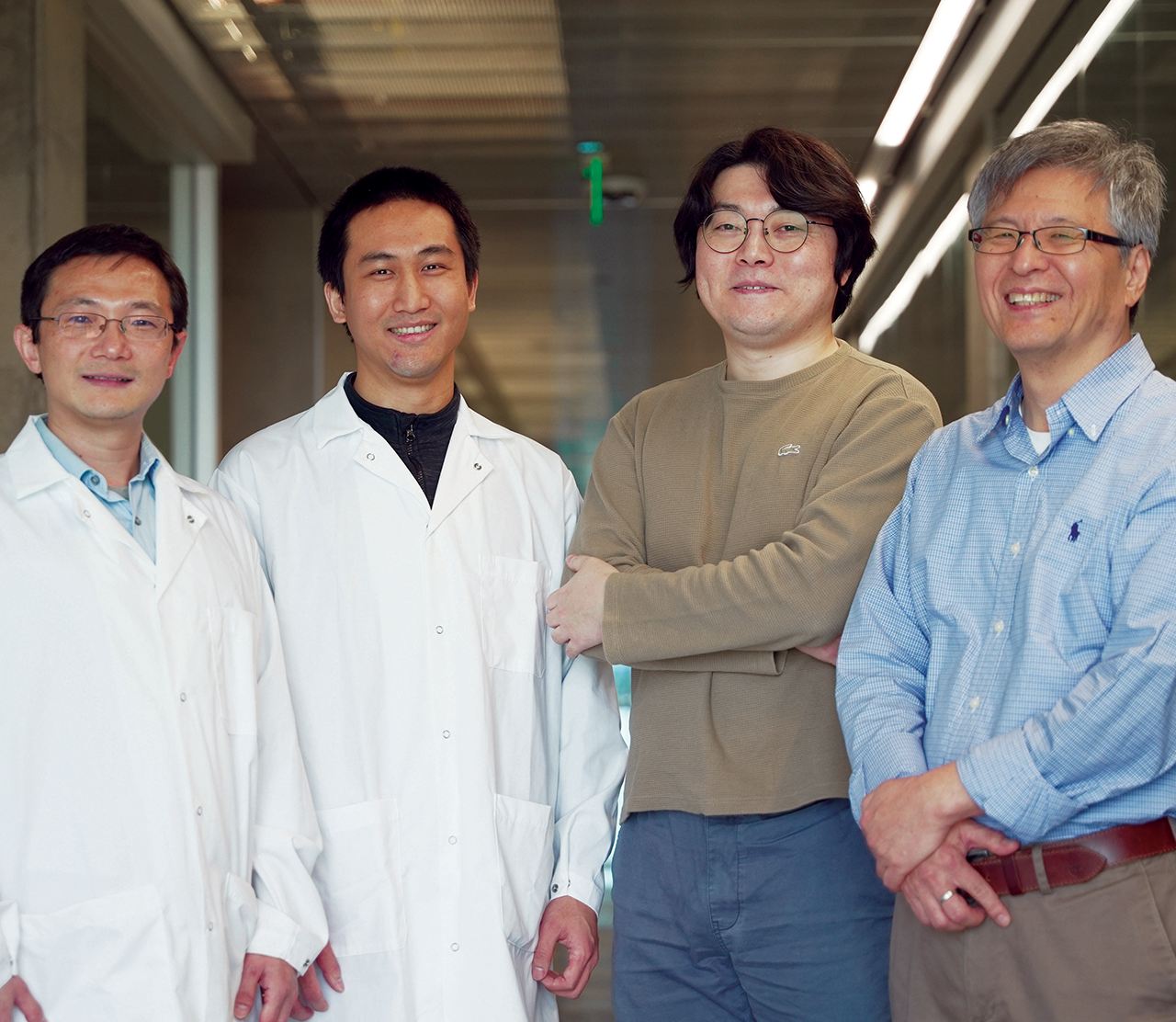

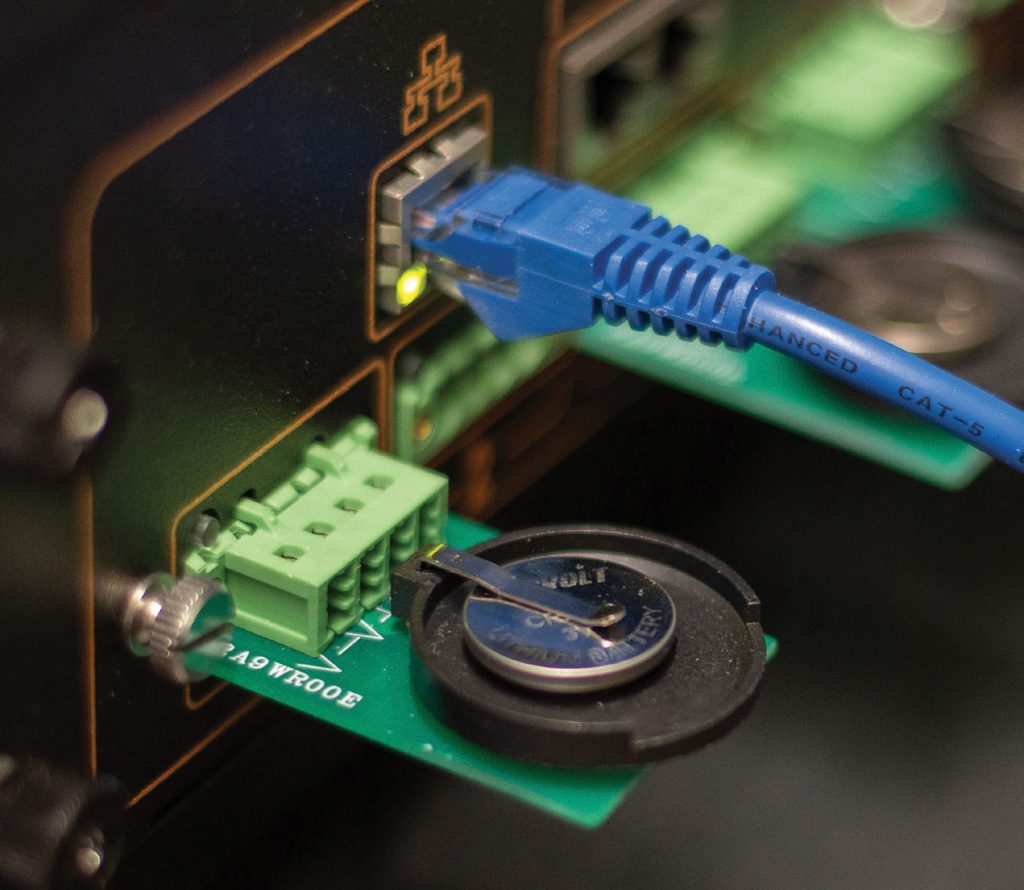

Xiong’s laboratory enables the testing of hundreds of coin cell batteries at once to expedite the research process.

“We look at nanoscale properties and interactions,” said Hwang, the postdoctoral researcher in Cho’s lab. “We were able to provide an atomic scale insight into how the water molecules would interact with the swelling lay, as well as how we could increase the cycle stability of the battery.”

Tian, the graduate researcher in Xiong’s lab, who on Oct. 27, 2023, successfully defended his PhD thesis “Interface Management for Safe and High-Performance Electrochemical Energy Storage Devices,” said, “It was really helpful to conduct experiments with the guidance of theoretical simulations. We predicted with modeling support that laponite is a superior swelling nanoclay to bentonite for separator-free AZIBs.”

The research on bentonite and laponite additives to AZIBs was published in summer 2023 in Advanced Energy Materials and ACS Nano.

Tian assembles a test battery using gloves and a protective box that prevents contaminants from entering the battery.

“I plan to work more on introducing inorganic materials into battery electrolytes,” Tian said. “We have several works in progress with exciting prospects.”

Cho is optimistic about future possibilities, due to the connections that have been established in Texas and across the United States.

“We are expanding well beyond our two labs,” Cho said. “As the U.S. transitions to more renewable energy, there are many relevant technologies that need to be developed. We are growing the strength of UT Dallas to bridge the theoretical side with the manufacturing side, where we have a direct impact on U.S. economic development. We have an opportunity to lead.”

UT DALLAS TO LEAD $30 MILLION BATTERY INITIATIVE

A UT Dallas researcher displays a battery after it is assembled in the glove box, a sealed container that is used when researchers work with hazardous and sensitive substances.

As announced by the Department of Defense (DOD) on Sept. 18, 2023, The University of Texas at Dallas will receive $30 million over three years from the DOD to develop and commercialize new battery technologies and manufacturing processes, enhance the domestic availability of critical raw materials and train high-quality workers for jobs in an expanding battery energy storage workforce.

The award, which creates a prototype Energy Storage Systems Campus, is the largest allocation from a federal agency that the University has received to date. The project will leverage and stimulate over $200 million in private capital.

Dr. Kyeongjae (KJ) Cho, professor of materials science and engineering in the Erik Jonsson School of Engineering and Computer Science and co-principal investigator, will lead the project as the director of the Batteries and Energy to Advance Commercialization and National Security (BEACONS) center.

Key partners include LEAP Manufacturing, a consortium of companies dedicated to the development and production of energy systems; Associated Universities, Inc. (AUI); the University of California, Berkeley; and the University of Chicago. The agreement provides funding from the DOD’s Manufacturing Capability Expansion and Investment Prioritization initiative.

“This initiative is a tremendous opportunity to showcase UTD’s mission of research, service and teaching in the context of accelerating workforce development and next-generation solutions that are critical to our nation’s economy and defense readiness,” said Dr. Richard C. Benson, UT Dallas president and the Eugene McDermott Distinguished University Chair of Leadership. “The expertise of our faculty researchers, the excellence of our academic programs in engineering and science and our demonstrated ability to leverage partnerships with industry put UTD in a unique position to lead this national effort to drive innovation in battery technology and manufacturing.”

The BEACONS center will focus on four main goals:

- Optimizing existing battery systems, including integrating robotics and automation into manufacturing

- Fostering the development of new battery chemistries that reduce the use of scarce raw materials

- Identifying and tracking supply chain challenges for critical minerals, such as lithium, needed in energy storage systems

- Developing the workforce needed for energy storage system development and manufacturing

Materials science and engineering doctoral student Manifa Noor mixes and grinds materials, including lithium salt, in one of the initial steps of the battery manufacturing process.

RESPONSE TO NATIONAL PRIORITIES

The National Blueprint for Lithium Batteries 2021-2030, published in 2021 by the Federal Consortium for Advanced Batteries, outlines several goals, including maintaining and advancing U.S. battery technology leadership by strongly supporting scientific research; science, technology, engineering and math education; and workforce development.

The agreement with the DOD is an outcome of more than a year of concerted efforts by UTD leaders and LEAP Manufacturing co-directors Dr. Thomas Campbell and John Stibal to respond to the federal agency’s request for proposals.

BEACONS will include multiple UTD researchers in the Jonsson School and the School of Natural Sciences and Mathematics who work on energy storage technology, including experts in computer modeling, artificial intelligence, chemistry, prototyping and commercialization. Their work will center on developing safer, longer lasting and more efficient next-generation battery technology, including alternatives to traditional lithium-ion cells.

UTD researchers are investigating current battery system optimization as well as next-generation batteries with alternative materials and designs, such as solid-state batteries, which use solid electrolytes instead of organic liquids or polymers, and aqueous zinc-ion batteries.

New Facility

The UT Dallas-led initiative will include construction of a research facility within a 1,200-acre area of the Richardson Innovation Quarter. The facility will include space for developing and manufacturing next-generation batteries, as well as energy storage solutions specifically tailored to defense applications. For example, defense systems operate at extremely cold or hot temperatures, encounter high shock and vibration, and may be stored for long periods before being needed quickly for immediate use. Defense battery systems also are sometimes operated in environments where safety demands exceed current commercial requirements.

While the U.S. has been a leader in battery research and technology development, battery manufacturing and supplies of critical raw materials have traditionally been located outside of the country. The DOD initiative reflects efforts to bring advanced manufacturing and supply chains to the U.S., Cho said.

“We identified a unique area that satisfies the Department of Defense’s needs for battery technology,” he said. “This investment by the DOD will facilitate collaboration with our industry partners to help ensure reliable, domestic manufacture of lithium-ion cells, and the battery packs that support defense systems and advanced commercial systems.”

Workforce Development | UTD Team

“Renewable energy is a rapidly expanding area, and Texas is leading the country in the expansion of energy storage capacity,” Cho said. “We need not only PhD-level experts, but also technicians who know how to safely handle batteries.”

In the News

KERA News

UT Dallas Lands $30M Project from Department of Defense to Research Battery Technology

Dallas Morning News

Defense Department to Invest $30M in UTD Battery Research

Dallas Business Journal

UT Dallas to Lead $30M Battery Technology Initiative from the Department of Defense

Dallas Innovates

Defense Department Awards $30M to Create UT Dallas ‘Energy Storage Systems Campus’

Community Impact

UT Dallas Receives $30M for Battery Technology Research, Workforce Development

The Register

DoD Hopes $30M BEACONS Will Light the Way to Next-Gen American Battery Designs

Researchers at UT Dallas and elsewhere are investigating how to make lithium-ion batteries safer and longer-lasting, more environmentally safe, and less reliant on expensive and rare minerals.

The initiative is a prototype for collaboration, said Dr. Joseph Pancrazio, vice president for research and innovation at UT Dallas and co-principal investigator on the project.

“UTD and our partners will ensure that laboratory research and creative ideas from small businesses translate quickly toward commercialization,” said Pancrazio, also a professor of bioengineering. “As a national resource, the collaborative space we’re creating will streamline the path of innovation in energy storage and battery technology, from prototyping and testing to manufacturing.

“Coupling technological advancement with workforce development ultimately will catalyze economic growth while bolstering national security.”